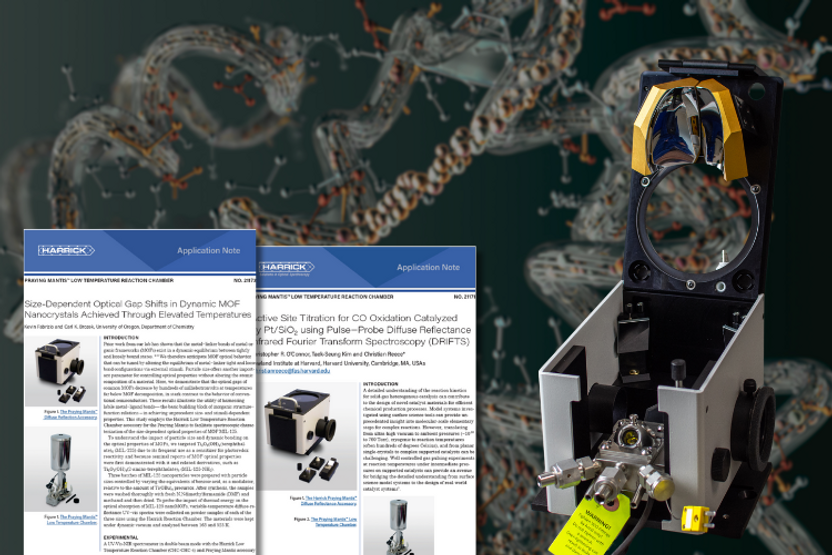

Applications of the Praying Mantis™ Low Temperature Reaction Chambers

Jul 11th 2024

We are pleased to share the latest customer application notes showcasing the kind of cutting-edge research that is enabled by the Praying Mantis™ Reaction Chambers.

1. Size-Dependent Optical Gap Shifts in Dynamic MOF Nanocrystals Achieved Through Elevated Temperatures

It is expected that the optical optical properties of metal-organic frameworks (MOF) can be tuned by varying their size. In this study, the MOF studied was MIL-125. This is a widely studied configuration and its properties were tuned by varying the amount of benzoic acid equivalents relative to the precursor. UV-Vis spectroscopy was employed on the MOF powders over a range of temperatures between 163 K and 523 K, and the effects on the optical gap are discussed in the note below.

Read the full application note

2. Active Site Titration for CO Oxidation Catalysed by Pt/SiO2 using Pulse−Probe Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS)

The pulse-probe diffuse reflectance IR spectroscopy method employed for this study aimed to study the evolution of reaction intermediates on the surface of the catalyst. Gas species were rapidly introduced to the Low Temperature Reaction Chamber under high vacuum. The results provide insights into the kinetics of heterogenous catalysis under conditions part way between the ultra-high vacuum, low-temperature set up of surface science experiments, and the high-temperature, ambient pressure environment of the full-scale reaction.

Read the full application note

About the Low Temperature Reaction Chamber

The chamber is designed for use with the Praying Mantis™ for collection of the diffuse reflection from a powder or solid sample by UV/Vis or IR analysis.

- Designed for studies from high vacuum (133 μPa or 10-6 torr) to 133 kPa (1 ktorr) and at temperatures from -150°C to 600°C (under vacuum).

- Three inlet/outlet ports provided for evacuating the cell and introducing gases.

- Made of chemically resistant 316 stainless steel.

Acknowledgement

With thanks to Kevin Fabrizio and Carl K. Brozek, University of Oregon, Department of Chemistry and Christopher R. O’Connor at the University of Harvard for the application notes included here.